DELLOK Stainless Steel Laser Welding Radiator Fin Tube

About us

Professional heat exchanger factory with 20 years of experience,

providing you with one-stop heat transfer solutions to design

different heat exchangers according to your purposes (metallurgy,

food, petrochemical, pharmaceutical, beverage, wastewater,

refrigeration, etc...)

Dellok Young is a professional manufacturer of various heat

exchangers integrating R&D, design, production and sales. The

heat exchangers produced are mainly used in petrochemical, electric

power, papermaking, building heating, mining and other industries,

such as air heaters, food industry plant protein powder, starch and

other air heater spray drying systems.

The company now has a professional technical innovation team and

professional after-sales personnel. The company's production plant

covers an area of approximately 18,000 square meters, has multiple

professional and advanced CNC and automated production equipment,

and has obtained a number of professional certificates and patents.

The company has a professional foreign trade team and has trade

cooperation with various regions. Some global partners conducted

on-site inspections of the production plants and were very

satisfied with the inspection results and established long-term

strategic cooperative relationships with our company.

Benefits of laser welded fin tubes

Laser welded

Fin Tube can avoid gap corrosion and have a longer service life

–Easy to clean and disinfect, the laser fins meet the requirements

of the food and pharmaceutical industry

-Optimum heat transfer, reduced materials, reduced footprint of

Heat Exchanger and lower investment costs

-Compliance with process flow, reduce downtime, reduce operation

and maintenance cost, investment cost

-The laser welded fin tube can be bent in the fin part, fast and

easily processed, reducing the bypass flow.

-The tube is almost unaffected by the welding process, with a

possible smaller tube wall, reduced footprint and weight of the fin

tube heat exchanger, and reduced manufacturing complexity.

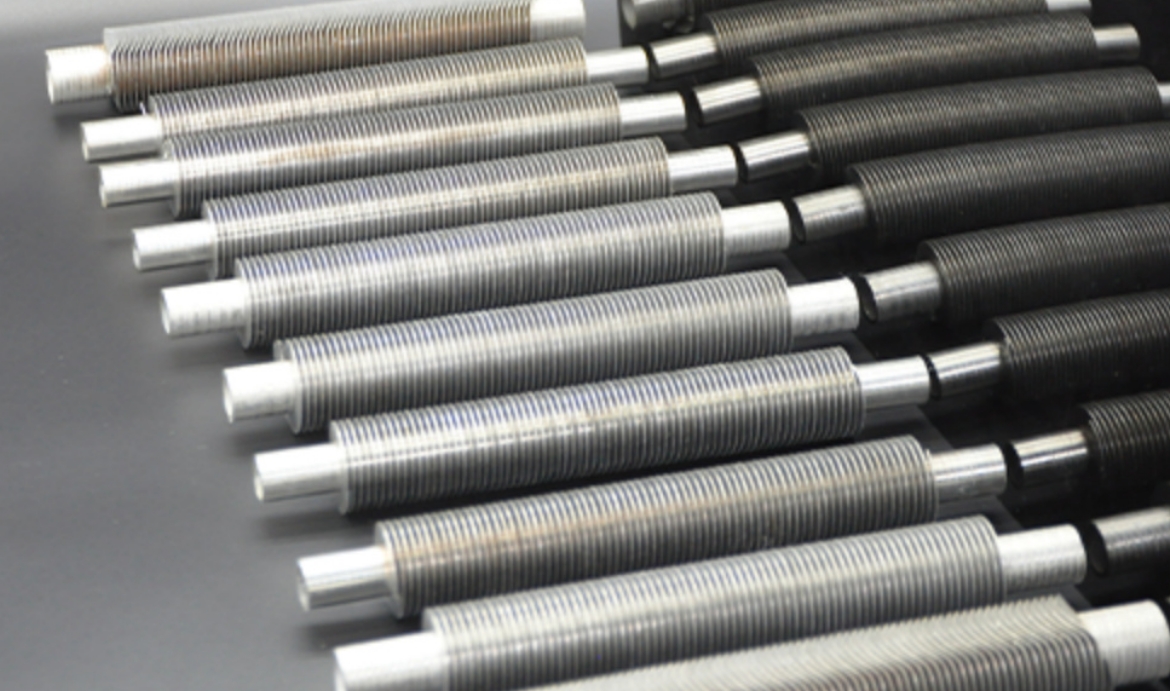

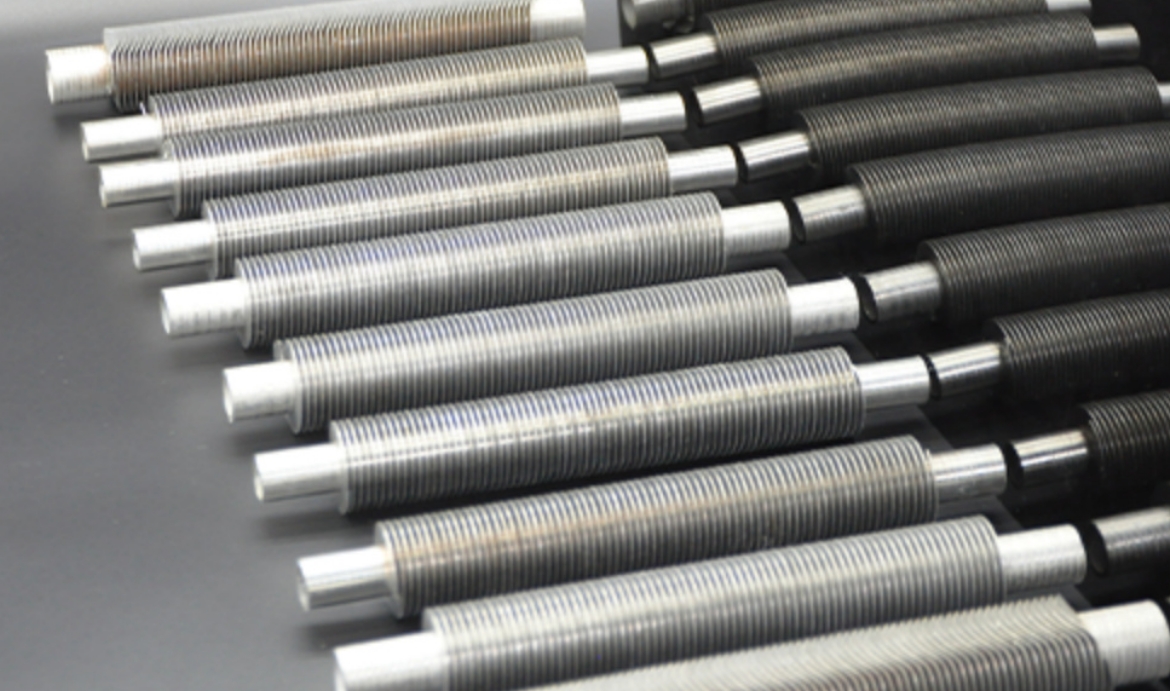

Laser-welded fin tube

Fin type: laser welded fin tube

Base pipe material: steel, aluminum, copper, titanium, etc

Heat material: copper, aluminum

Wender tube length: unlimited

Product Description: 100% welded between fin and tube without

filling material.The laser welding in the weld.

100% welding between fin and tube without use of filling

material.There are no impurities on the weld for laser welding in a

protective atmosphere.Different material of the fins and

tubes.Simple bending and coiling of the fin tube.Since the

heat-affected areas and welds are small, the material does not

deform, while the tubes and fins have only slight microstructural

changes.

Benefits of fin tubes

Avoid gap corrosion and have a longer service life

–Easy to clean and disinfect, the laser fins meet the requirements

of the food and pharmaceutical industry

-Optimum heat transfer, reduced materials, reduced footprint of

heat exchanger and lower investment costs

-Compliance with process flow, reduce downtime, reduce operation

and maintenance cost, investment cost

-The tube can be bent in the fin part, fast and easily processed,

reducing the bypass flow.

-The tube is almost unaffected by the welding process, with a

possible smaller tube wall, reduced footprint and weight of the fin

tube heat exchanger, and reduced manufacturing complexity.

Laser-welded fin tube specification.

·Pipe outer diameter 8.0-50.0 mm Wing outer diameter 17.0-80.0 mm

wing pitch 5-13 fins / inch wing height 5.0-17 mm fin thickness 0.4

1.0 mm maximum pipe length 12.0 m.

range of use:

usually,Squeeze wings Utend Power plant, chemical industry, heat recovery plant, thermal

industry

The maximum operating temperature is 400 C.

Murphy products as below:

High Frequency Welded Fin Tube

U Bend Tube For Heat Transfer

H/HH Type Fin Tube

Intergral High Finned Tube

G Finned Tube

Intergral Low Finned Tube

Longitudinal Finned Tube

Studded Tube

L/LL/KL/KL/ Finned Tube

Laser Welded Finned Tube

Fin Tube Coil

Extruded Finned Tube

Tubular Heat Exchanger

Plate Heat Exchanger

Finned Tube Heat Exchanger

Brazed Heat Exchanger

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome

to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality.

Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30

days, also depends on your request.

Q4: What is the warranty for your products?