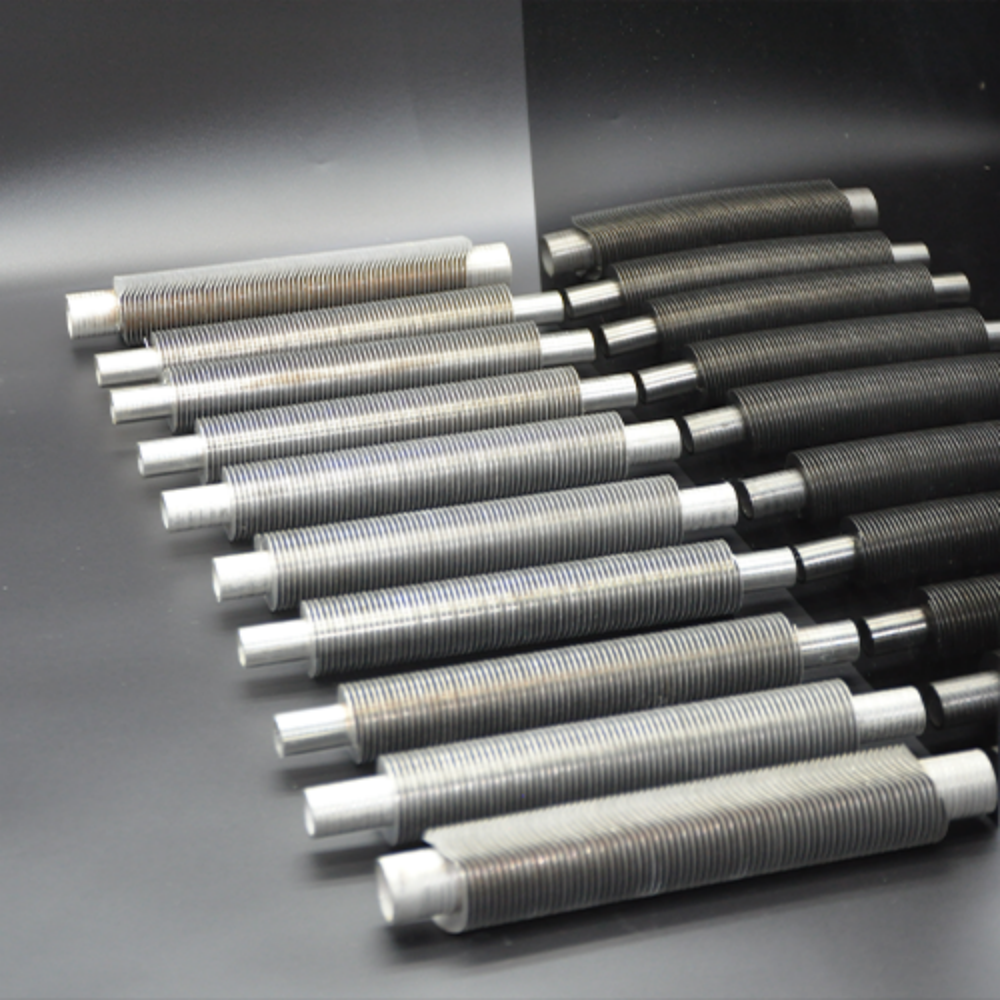

Laser

Welded Finned Tube Product Description:

1.Thin and continuous ideal seams

2.Small heat affected area

3.Slightly discolored welding parts

4.The tubes and fins have only slight microstructure changes

5.High heat forms seams

6.Since the high welding integrity between the tube and the fins is

avoided, the crevice corrosion is avoided, thereby improving safety

7.Laser welding is carried out in a protective atmosphere, so the

weld is free of impurities

Laser Welding Fin Tube Manufacturing Process:

Laser welding is a high intensity laser beam to the metal surface,

through the interaction of laser and metal, metal absorption laser

into heat to make the metal melt after the formation of cooling

crystallization welding.

Laser Welding Fin

Tube(Welded

Spiral Pipe) Advantages:

1.The thickness of base tube and fin can be 0.8-1.5 mm and 0.3-1 mm

respectively, which greatly saves the material cost compared with

other processes.

2.High penetration rate can prevent gap corrosion, prolong service

life and reduce heat transfer resistance.

3.No material restriction, different materials can be used for

processing.

4.Easy for secondary processing, can be directly coiled and bent.

5.The welding heat affected zone and the metallographic change are

small, which makes it possible to process the small diameter finned

tube.

6.A variety of material combinations are available, titanium/

copper, titanium/titanium, carbon steel/carbon steel, stainless

steel/stainless steel, stainless steel/copper, etc.

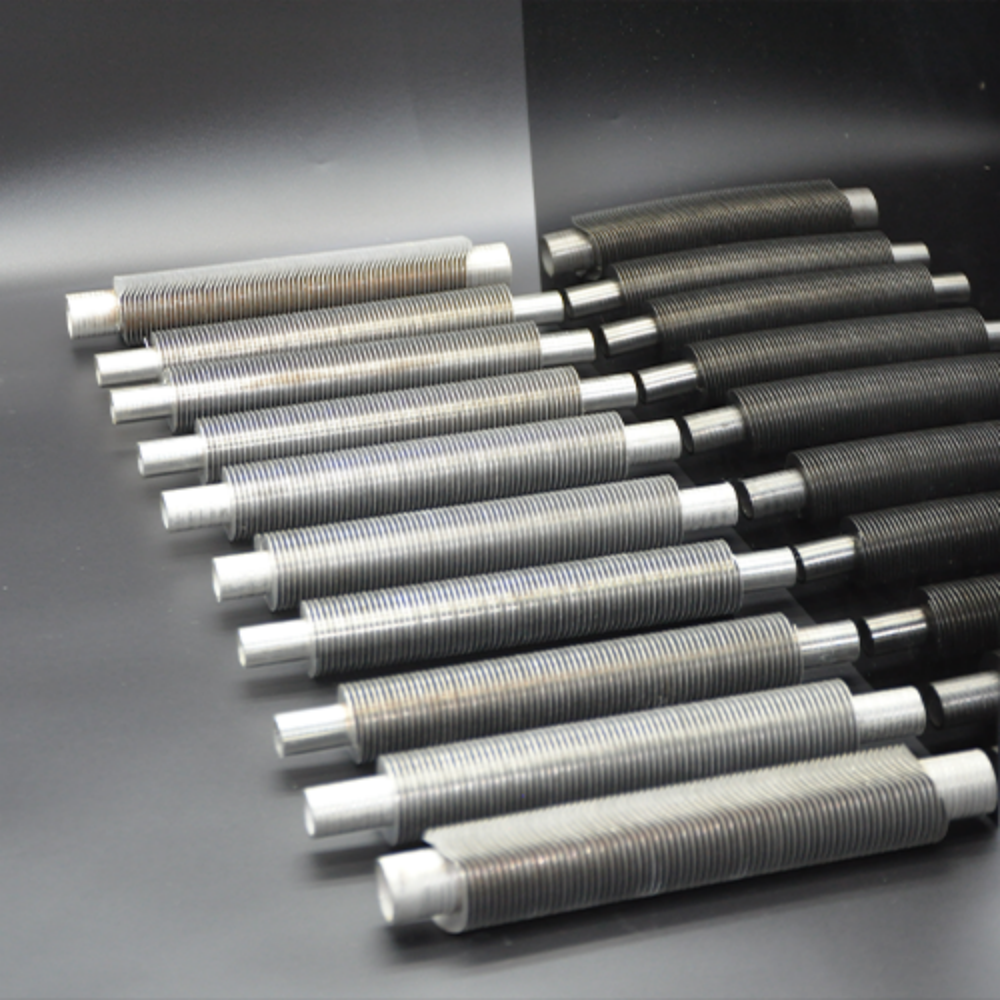

Laser Welded Finned Tube(Stainless

Steel Welded Pipes) Properties:

1.Advanced technology: the product using laser welding technology,

100% penetration rate.

2.Stable quality: the equipment using full automatic production

process, product quality is stable and reliable.

3.High heat efficiency: the product has smaller fin spacing and

thin tubes to increase the heat transfer area and heat transfer

rate.

4.It can be bent into different shapes to meet different production

needs.

Laser Welded Finned Tube(Stainless

Steel Welded Pipe) Applications:

1.Power Plants

Cooling towers or cooling water recooling plants with dry, dry /

wet or wet operation

Sodium coolers for Fast Breeder power plants

Flue gas cooling and heating in fl ue gas desulfurisation scrubbers

(FGD) and nitrogen removing plants

2.Chemical and Pharmaceutical Industry Food & Beverage

Heat exchangers of all kinds for cooling and heating of liquids and

gases

Heat exchangers for nitric acid (HNO3) plants, e.g. for the

fertilizer industry

Heat exchangers for milk powder production

3.Heat Recovery Plants

Flue gas coolers

Economizers

Waste Heat Recovery Units (WHRU)Heating Industry

Primary heat exchangers in gas heating boilers

Secondary heat exchangers for domestic water heating in condensing

boilers

4.General Engineering

Heat exchangers for gas cooling of industrial furnaces

Heat exchangers for tank heating

Oil coolers for vacuum plants, ship plants, pumps etc.

Heat exchangers for oil preheating

Laser Welded Finned Tube(Spiral

Welding Pipe) Specifications:

| Product Specification |

| Tube OD | 10~215 (mm) | 0.4”~8.5” |

| Tube Wall Thk | 1~6 (mm) | 0.04”~0.24” |

| Tube Length | ≤18,500 (mm) | ≤60.7ft |

| Fin Thk | 0.3~2.0 (mm) | 0.01”~0.08” |

| Fin Height | 3~30 (mm) | 0.12”~1.2” |

| Fin Pitch | 2~20 (mm) | 1~13 FPI |

| Fin Type | Solid, Serrated |

| Material Combinations |

| Fin Material | S.S. |

| C.S. |

| Aluminum |

| Copper |

| Titanium |

| Tube Material | S.S. |

| C.S. |

| Copper |

| Titanium |

| Applied | 450°C |

| Temperature |

| Type of Service | High temperature |

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome

to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality.

Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30

days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.

Q5: What payment terms do you accept?

A :Trade assurance,TT,Western Union.