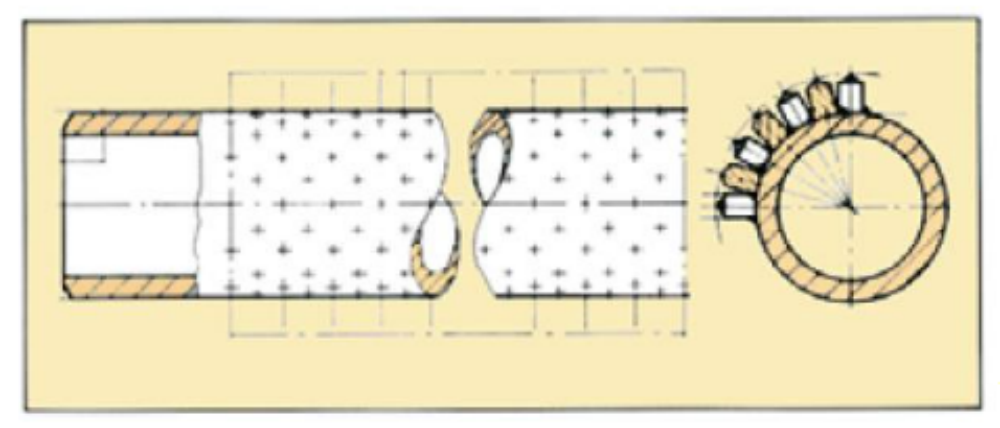

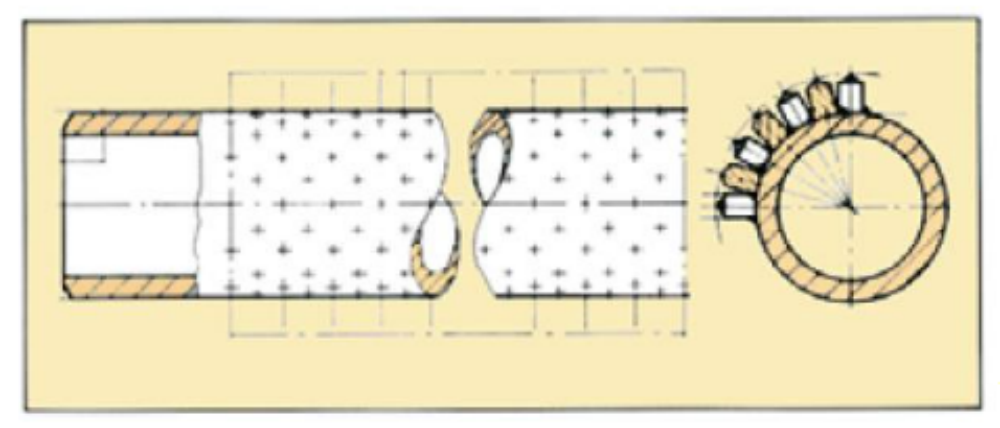

STUDDED TUBE

Studded tubes are used as substitution of finned tubes for heat

transfer in the petrochemical industry, generally in fired heaters

and boilers where the surface is exposed to a very corrosive

environment and where very dirty soot formation require frequent or

aggressive cleaning.

FABRICATION PROCESS

The studs are automatically welded to the tube by electric

resistance welding machine. The welding process is controlled by

PLC program, stepping motor, indexing adopt brake motor. All the

welding parameters such as number of studs, pitch, compensation

coefficient etc. are input via human machine interface(HMI),

Product quality could be guaranteed by the settings according to

the process requirements.

The automatic stud feeder was developed by our engineers combining

both our large experience manufacturing extended surface and the

most modern control technology available in the market. The

technology has benefited us with more efficient production and

consistent welding quality.

APPLICAITONS

Murphy's studded tubes are generally installed in the convection

sections and boilers where the surface is exposed to a severe

operating case of dirty flue gas.

Frequently Asked Questions (FAQ) About Studded Tubes:

1. What is a Studded Tube?

Studded tubes are a type of metal tubes. These tubes have studs

welded onto the metal tube.

These studs are arranged in a specific formation throughout the

length of the tube.

They are often used in boilers and refineries. As they increase the

surface area for higher heat transfer they are used for reheating.

2. Why use studded tubes?

The heat exchange efficiency is equivalent to 2-3 times that of the

bare pipe.

Easier cleaning especially for operating cases with very dirty flue

gas produced by burning heavy oil, diesel or residual oil.

To increase the film heat transfer coefficient of flue gas to the

furnace tube.

Increase efficiency in the process of heat recovery and direct

flame hostile atmospheres.

Reduce the amount of bare pipes used in these processes. (Heat

transfer surface of one studded pipe is equivalent to surface of 4

to 10 bare pipes). Stud Pipe's ideal for processes applications

where dirty fuels are used and harsh environments in terms of

temperature and/or corrosion.

Studded fin tube is a standard frequency electric-resistance-welded

studded type surface. It is normally manufactured with round carbon

steed studs on carbon, alloy or stainless steel tubes with

diameters from 1.5" to 12.75".

3. What are the important factors for high frequency welding?

The four most important factors / process parameters influence High

frequency welding are

Electrical power

Pressure applied

Welding time

Cooling time

Finding the optimal process parameters will depend on your specific

equipment, the materials involved and the specific geometries

including thickness and area to be welded. Achieving optimal

results is often an experimental process guided by experience. As a

guiding rule, the thicker material and focus on short weld times

you need, the stronger electrical power / HF generator you need.

4. What is High Frequency welding?

High frequency welding (often abbreviated HF welding or RF welding)

is a manufacturing process where two plastic parts are welded

together using an electromagnetic field. The resulting join can be

very strong – often close to the original strength of the materials

joined. In some scenarios the weld can be even stronger than the

original materials.

Using a high frequency electromagnetic field, the material is

heated and pressure added to melt and fuse the two materials

together. No outside heart is applied. Instead the heat is

generated within the materials. During cooling (under continued

pressure), the materials are fused together and a weld has been

created. This results in a very strong bond between the two parts.

5. Where are Studded Tubes used?

Studded tubes are used instead of finned tubes for heat transfer in

the processing industries, generally in furnaces, gas turbines,

fired heaters and furnace applications where the surface is exposed

to a very corrosive environment and where very dirty gas streams

require frequent or aggressive cleaning.

6. How do you control your quality?

We always put quality as the most important thing for customers,

and we control the quality from raw material inspection, production

checking to water pressure test and strength test. Also the third

party can be authorized to check.

Incoming inspection report for bare tube & strip.

Mill test certification for bare tube

Mill test certification for fin

Mill test certification for finned tube

Finned tubes dimension & visual inspection reports