DELLOK C44300 Embedded Fin Tube For Cooler

About us

Professional heat exchanger factory with 20 years of experience,

providing you with one-stop heat transfer solutions to design

different heat exchangers according to your purposes (metallurgy,

food, petrochemical, pharmaceutical, beverage, wastewater,

refrigeration, etc...)

Dellok Young is a professional manufacturer of various heat

exchangers integrating R&D, design, production and sales. The

heat exchangers produced are mainly used in petrochemical, electric

power, papermaking, building heating, mining and other industries,

such as air heaters, food industry plant protein powder, starch and

other air heater spray drying systems.

The company now has a professional technical innovation team and

professional after-sales personnel. The company's production plant

covers an area of approximately 18,000 square meters, has multiple

professional and advanced CNC and automated production equipment,

and has obtained a number of professional certificates and patents.

The company has a professional foreign trade team and has trade

cooperation with various regions. Some global partners conducted

on-site inspections of the production plants and were very

satisfied with the inspection results and established long-term

strategic cooperative relationships with our company.

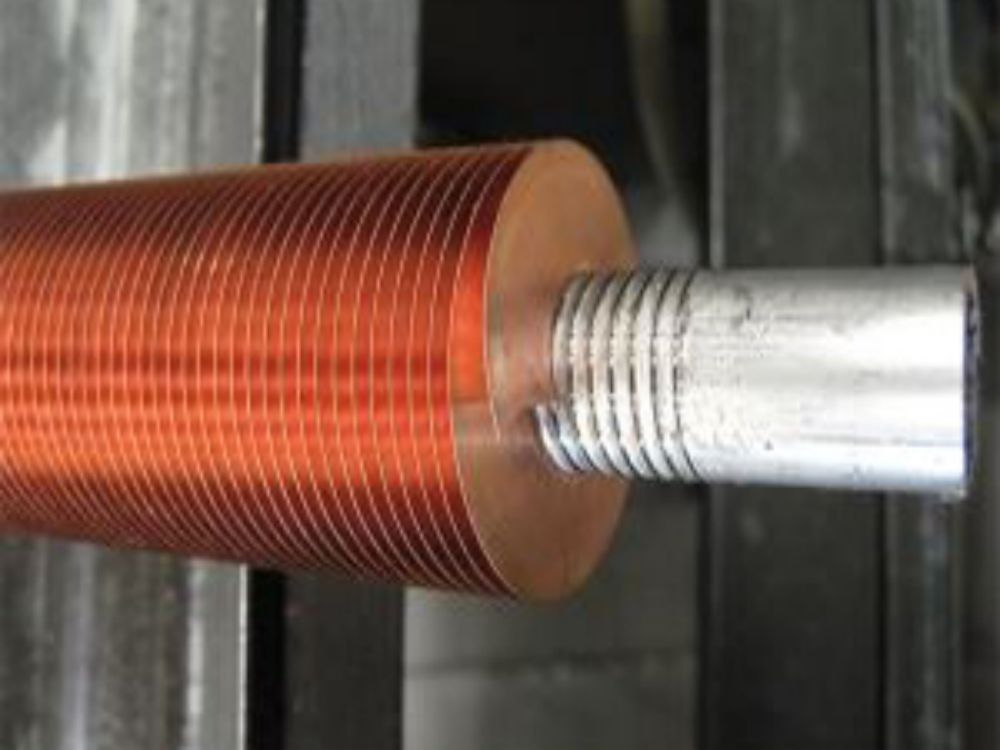

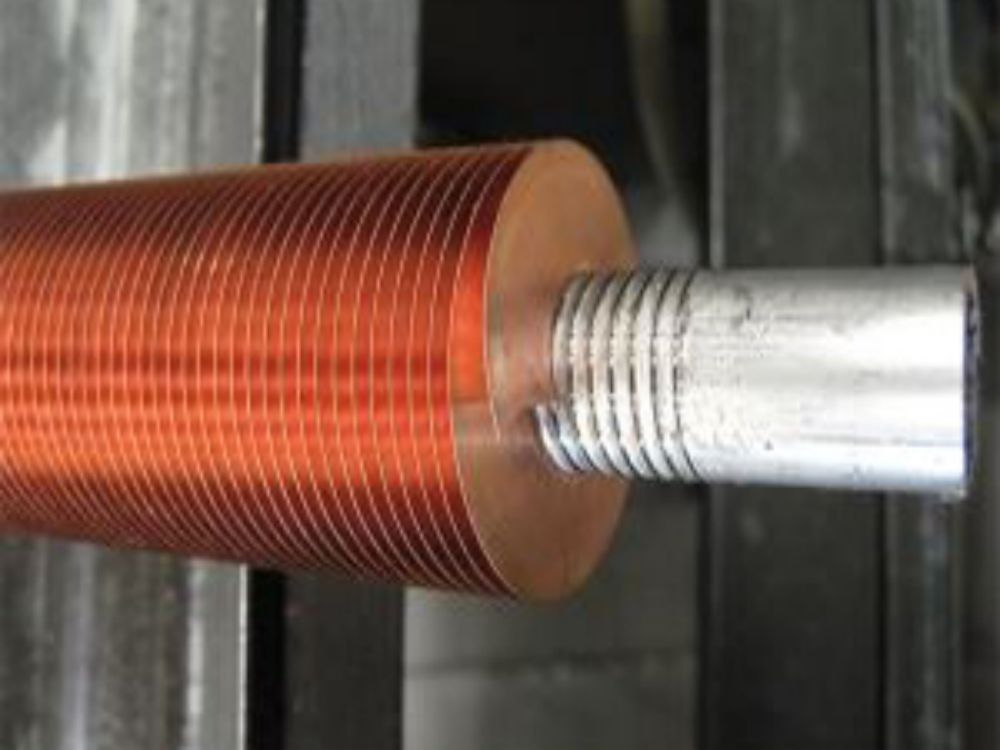

Product Description

The fin strip is wound into a machined groove and securely locked

into place by back filling with base tube material. This ensures

that maximum heat transfer is maintained at high tube metal

temperatures.

G Finned Tube Manufacturing Process

The manufacturing tool is made up of 2 non-cutting plates set at

90° to the axis of the base tubes (core tube).The first plate

effects a groove for metal spinning. The second directs the ribbon

in the groove and sets the fin foot in the groove through pressure

on the metal displaced for the groove. A similar plate made of

tungsten carburate allows us to manufacture. G embedded fin tubes (

fin tubes )with base tubes (core tube) made of austenitic steel or

exotic alloys.

G Finned Tube Advantages

1)Thermal

The fin/tube wall contact is constant because of the setting and

makes it possible to use a wall temperature of up to 400°C.

2)Mechanical

The fin is set throughout its length and consequently does not

unwind even when partially uprooted.

G Finned Tube Properties

High heating efficiency and heating up fast, small volume, small

wind resistance, installation is convenient wait for a

characteristic, can be installed in a wind pipe and the by-pass

pipe.

G Finned Tube Applications

petroleum, chemical and petrochemical industries

natural gas treatment

Steel industry: blast furnace and converter system

power generation: steam turbine exhaust gas condensation,

condensation water contact circulation cooling condensation

air conditioning (freon, ammonia, propane)

waste incineration equipment

compressor cooler, etc

G Finned Tube Specifications

| Product Specification |

| Tube OD | 19~51 (mm) | 3/8”~2” |

| Tube Wall Thk | 2.11~3.5(mm) | 0.083”~0.138” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.012”~0.02” |

| Fin Height | 10~16 (mm) | 0.394”~0.63” |

| Fin Pitch | 100~433 FPM | 3~11 FPI |

| Fin Type | G |

| Material Combinations |

| Fin Material | Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) |

| Copper |

| Tube Material | C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) |

| S.S. (most common grade: TP304, 316) |

| Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi

90/10) |

| Titanium (most common grade: B338Gr2) |

| Applied | 400°C |

| Temperature |

| Type of Service | High temperature |

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome

to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality.

Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30

days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.

Q5: What payment terms do you accept?

A :Trade assurance,TT,Western Union.

Q6: What are the modes of transportation of machines?

A: Air freight, sea freight express delivery, etc. We will choose

the most suitable transportation method according to your

requirements.Low fin Tube