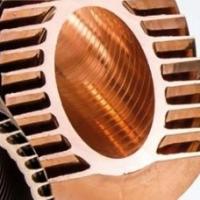

Fin Type: Extruded Fin Tube

Tube Material: copper, copper nickel, stainless steel, titanium

etc.

Fin Material: Copper, aluminum

Aluminum extruded finned tubes using the form of the base tube

covered with aluminum tube(the base tube can be carbon steel,

stainless steel, copper) through machine extrusion, forming a tube

fin, the fin base and the tube outer wall is close fitting, this

fin tubing control can make finned tubes with high heat transfer

coefficient and heat transfer performance.

Aluminum extruded finned tubes, also called [integral finned tubes"

using the form of the base tube covered with aluminum tube(the base

tube can be carbon steel, stainless steel, copper) through machine

extrusion, forming a tube fin, the fin base and the tube outer wall

is close fitting, this fin tubing control can make finned tubes

with high heat transfer coefficient and heat transfer performance. Extruded

Finned Tube can be made of iron, copper or aluminum tube by compound rolling,

which has the advantages of tight bonding, small thermal

resistance, good heat transfer performance, high strength, small

flow loss, strong anti-corrosion performance, not easy to

deformation under long-term hot and cold working conditions, long

working life and so on.

Extruded finned tube manufacturing process

Pipe line--compressing or rolling--strip peeling--washing--pressure

test--blast blowing--packaging.

The Extruded Fin Tube is formed by a bimetallic tube consisting of an aluminum outer

tube and an inner tube of almost any material. The fin is formed by

rolling the material from the outside of the outer tube to provide

an integrated fin with excellent heat transfer performance and

life. The extruded fins provide excellent corrosion protection for

the base tube.

The production method of the composite finned tube mainly includes

the extrusion method: the bimetallic composite tube is lined with a

mandrel, and driven by the rotation of the roller blade, the

composite tube is processed on the outer surface through the cavity

formed by the rolling groove and the core head Out fins. The heat

transfer tube produced by this method is an organic whole with its

outer tube and fins, so there is no problem of contact heat loss,

and it has good performance and high heat transfer efficiency.

FAQ

1. What Does Fin Tube Mean?

A fin tube is a tube that has small fins around the outside

surface. These fins act as a filter and a mechanism to transfer

heat from the material inside the tube to the outside space or vice

versa. Fin tubes are used in applications that require a transfer

of heat from a hot fluid to a colder fluid through the tube's wall.

The rate at which such heat transfer occurs depends on three

factors:

The temperature difference between the two fluids.

The heat transfer coefficient between each of the fluids and the

tube wall.

The surface area to which the fluid is exposed.

2. Where is finned tube heat exchanger used?

Finned tube heat exchangers generally use air to cool or heat

fluids such as air, water, oil or gas, or they can be used to

capture or recover waste heat. These heat exchangers can used in a

broad range of industries including oil & gas, power generation,

marine and HVAC&R.

3. What is extruded fin tube?

Extruded finned tubes are bimetallic tubes whose outer aluminium

surface is finned by cold plastic deformation. There are two major

types of finned tubes available with us, single metal tubes (also

called mono metallic fin tube) and Bimetallic tube (composite

extruded fin tube) .

4. Why Aluminium is recommended as a fin material?

Good corrosion resistance, formability and high thermal

conductivity make aluminium an ideal material for the construction

of these heat exchangers. A typical brazed heat exchanger (radiator

or condenser) comprises fins, tubes, sideplates and headerplates.

5. Where are extruded fin tubes used?

Extruded Fin Tubes are widely used in the refinery, petrochemical

and chemical industry for:

Air-cooled condensers

Air-cooled coolers for products

Gas coolers

Gas heaters

6. How do you ensure a quality product?

We adhere to an in-house Quality System (or QMS) based on Industry

Standards such as ASME, the National Board of Boilers & Pressure

Vessels, and customer requirements. Our quality system is

documented, audited, and enforced by our Quality Control

department.